If you are a retailer and are looking for the best practices to perform a stock audit, you may come across a list of it on the internet which is 100% false. You wouldn’t believe if the list had said “The Earth is flat” or “The Sun revolves around the Earth” but believe the so-called “best practices of stocktake”? We bet you’d be shocked to find the actual truth behind them.

1. Perform inventory audit at least once a month. Do you really have to?

It is a myth that a stock audit cannot be done perpetually. You trust the myth, you feel stock audit as a headache. You feel it as a headache, you barely do it. You do it, you face multiple challenges like pausing sales, arranging the store first, paying extra wages to your employees’ extra efforts, etc. But, you would have never realized the real reason behind your improper inventory management having led to unfavorable stocktake results.

So, here’s the best deal! Daily stocktake is just one click away and is made easily possible with our stocktake app. You can count stock and perform live reconciliation while your sales are on. All you have to do is sit back and feel the complete control over your inventory with incremental stocktake.

2. Remove damaged items from racks before the stock audit. Do you really have to?

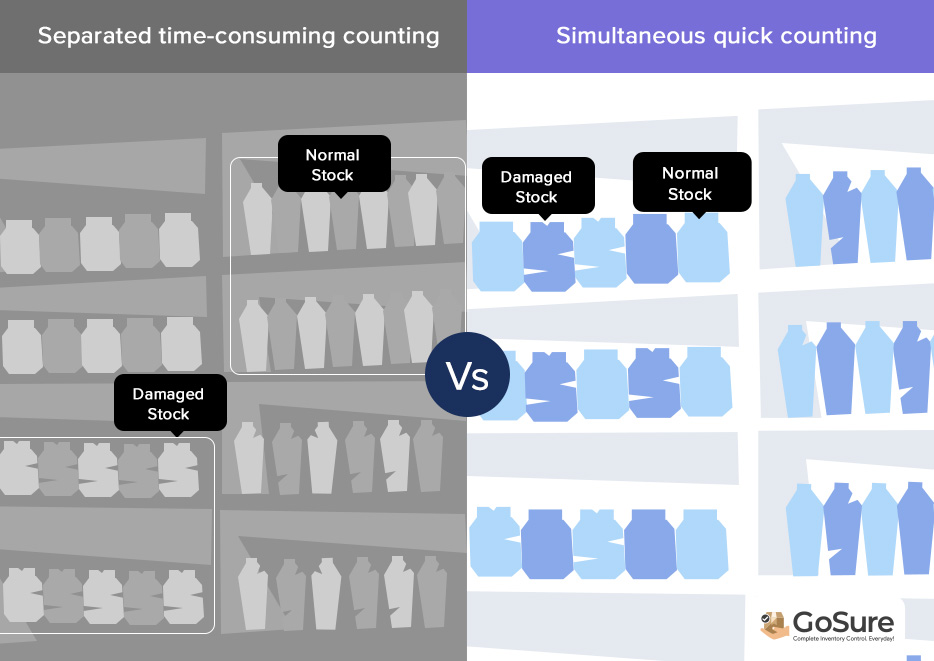

It is always best advised to clear up the damaged items before stock counting to avoid confusion and so, you might have deployed a damaged-stock picker to collect all the damaged goods from the entire store hoping for good inventory audit results.

But, we believe a good business like you, wouldn’t do that mistake of wasting time in unnecessary steps like these. Using a technology which could help you capture the damaged products side by side during the audit can help you avoid confusion and reduce your stock counting time by 50%

3. Use sufficient paper and pen. Do you really have to?

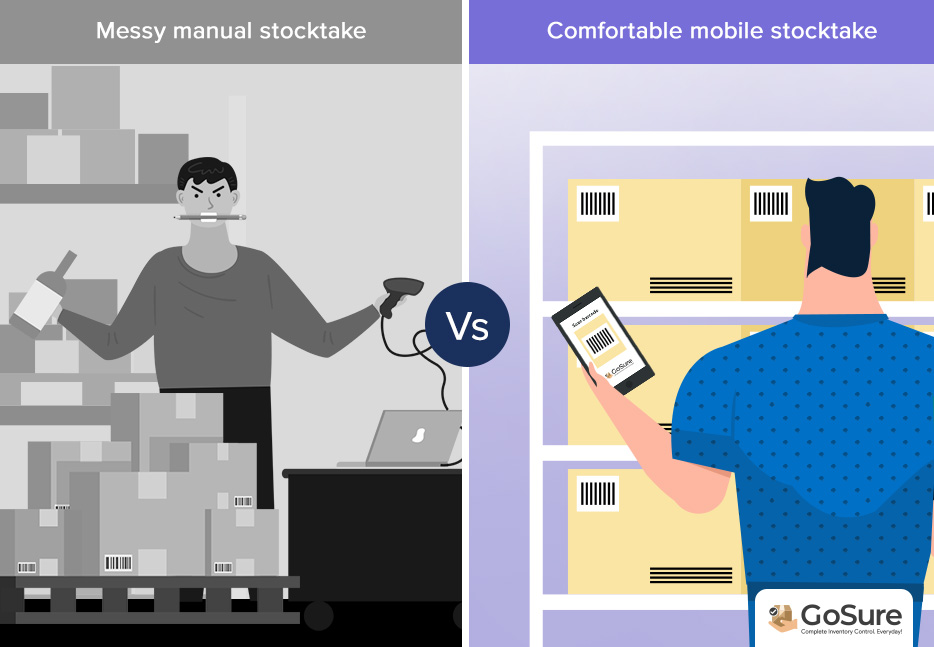

Ever thought of saving the money spent on quires of paper for inventory audit and contributing to nature? Facts reveal, every time a retailer does a stock audit, he cuts down half a tree! Also, papers would have been difficult to handle, maintain and arrive at accurate results making the entire process seem all the more messy.

Step up and stand ahead! Avoid frustration due to wrong entries, missing copies of sheets, reviewing manual errors and reprinting pages for re-count. Feel pressure-free and error-free stock count with employees’ mobile stocktake app.

4. Invest in a good quality barcode scanners. Do you really have to?

The problem does not just end there. For many, juggling between paper, stationery items and the barcode scanner eats up most of their stock take time and reduces accuracy too. Whereas, some have the habit of renting a third-party agency and getting this headache of a task done, which is dead unwise to think of, having a mobile phone in hand.

What if your mobile phone cameras can turn into barcode scanners for an effortless quick stock audit? Choose the intelligent, easier and more economical way today by making use of your mobiles to the fullest for your inventory management.

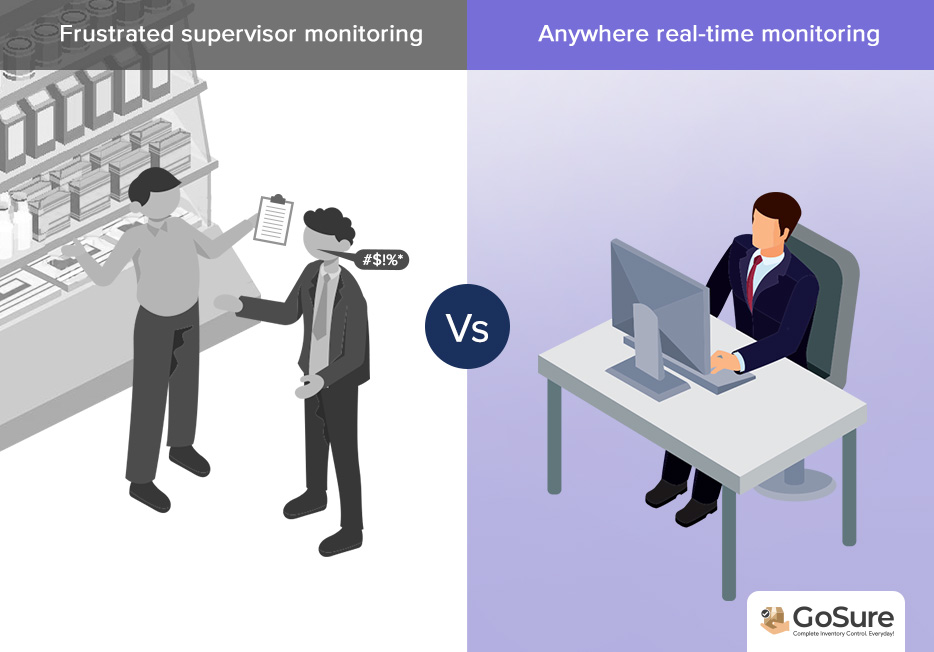

5. Always appoint a supervisor to monitor stocktake teams. Do you really have to?

From a business owner’s point of view, it is always difficult to trust your employees when it comes down to stocktake. So, your natural thought would be to appoint a supervisor, who is a skilled person for each stocktake team and monitor them constantly, even if it costs you more. But, have you ever realized how much of a dependency on the skills of a person, have created on you like monitoring the process, stock verification, reconciliation, etc,.?

Now, with live tracking of stock counting activities and real-time reports made possible, a supervisor is no more needed. So why not grab a doughnut and have an eye on the stock counting process anytime, anywhere with our stocktake app?

6. Spend more or equal time on inventory reconciliation as well. Do you really have to?

Stock counting can be done with, but what about reconciliation? Hasn’t it always been the major time-consuming part with reviewing, re-assigning, re-checking and finally updating the physical stock? Most business owners like you still wonder where some products go missing, even after finishing an end-to-end stock counting. With large SKUs comes large responsibilities and reconciling the data with the use of excel sheets takes hours and in some cases, days too!

Wave goodbye to the struggles of maintaining excel sheets and following multiple steps to arrive at unsatisfied results. Worry no more with detailed reports including your pending / missing products with stock counting during business hours. Step into the one-click real-time reconciliation process and get system driven instant reports in one click at any given time. Never lose confidence over your inventory investment.

The shocking truths definitely have broken the popular myths helping more than 600 retailers perform a regular inventory audit. We are sure this blog will help you dilute your cost and expenses with regards to inventory management. You may compare, test and then believe the truth. But, stand out of the crowd and choose the smart way to win complete inventory control!